PROJECT BACKGROUND

The Arnhem Land Progress Aboriginal Corporation (ALPA) is Australia’s largest Independent Aboriginal Corporation. They lead the way in Remote Retailing, Community Service Program Delivery, Enterprise, Economic Development and Corporate Services.

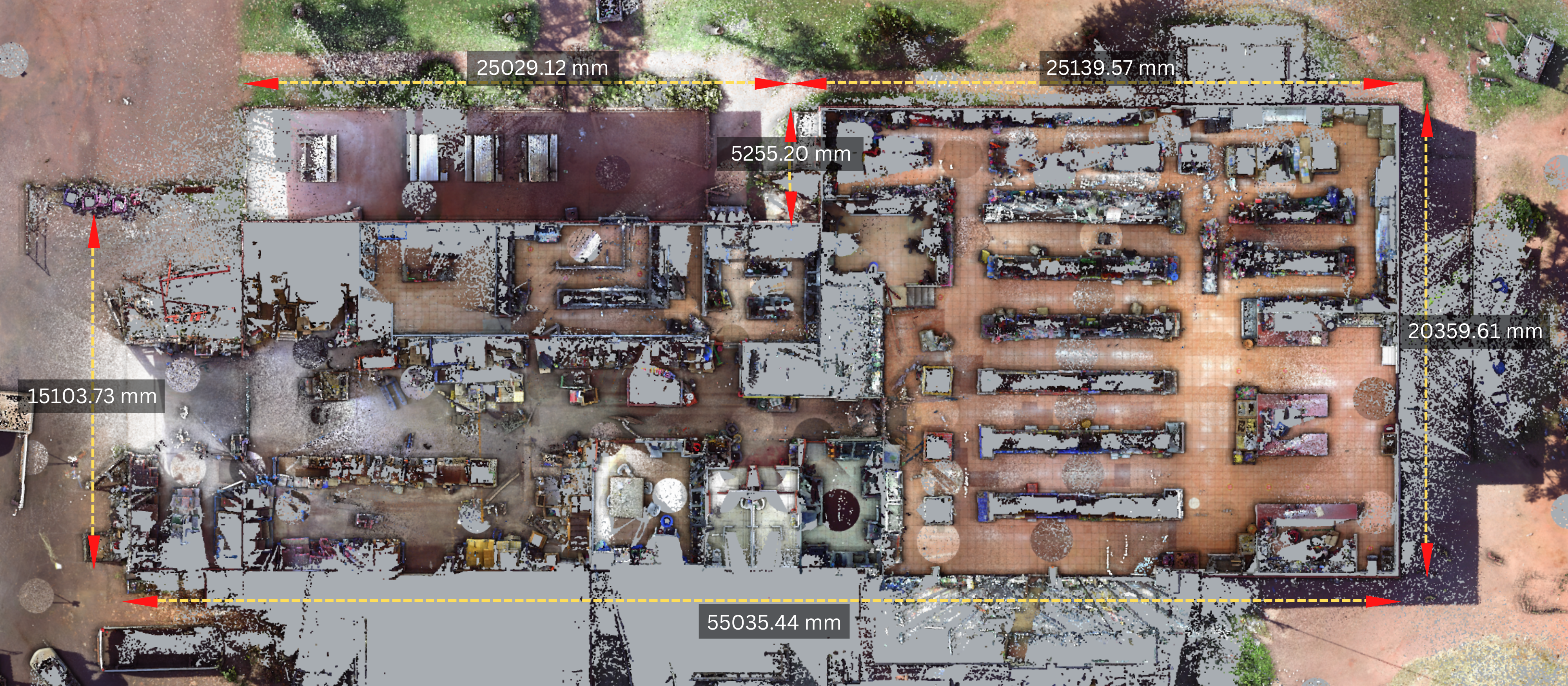

Holovision NT was engaged by ALPA to trial our 3D Laser Scanning & Visualisation solutions to assess how it would improve upon their previous facilities management practices for their 27 stores located in remote communities across the Northern Territory.

The challenges of these practices were mostly due to the remoteness of the sites, travel logistics and thus traditional contractors’ inability to adequately and efficiently measure the sites, requiring repetitive and costly site visits.

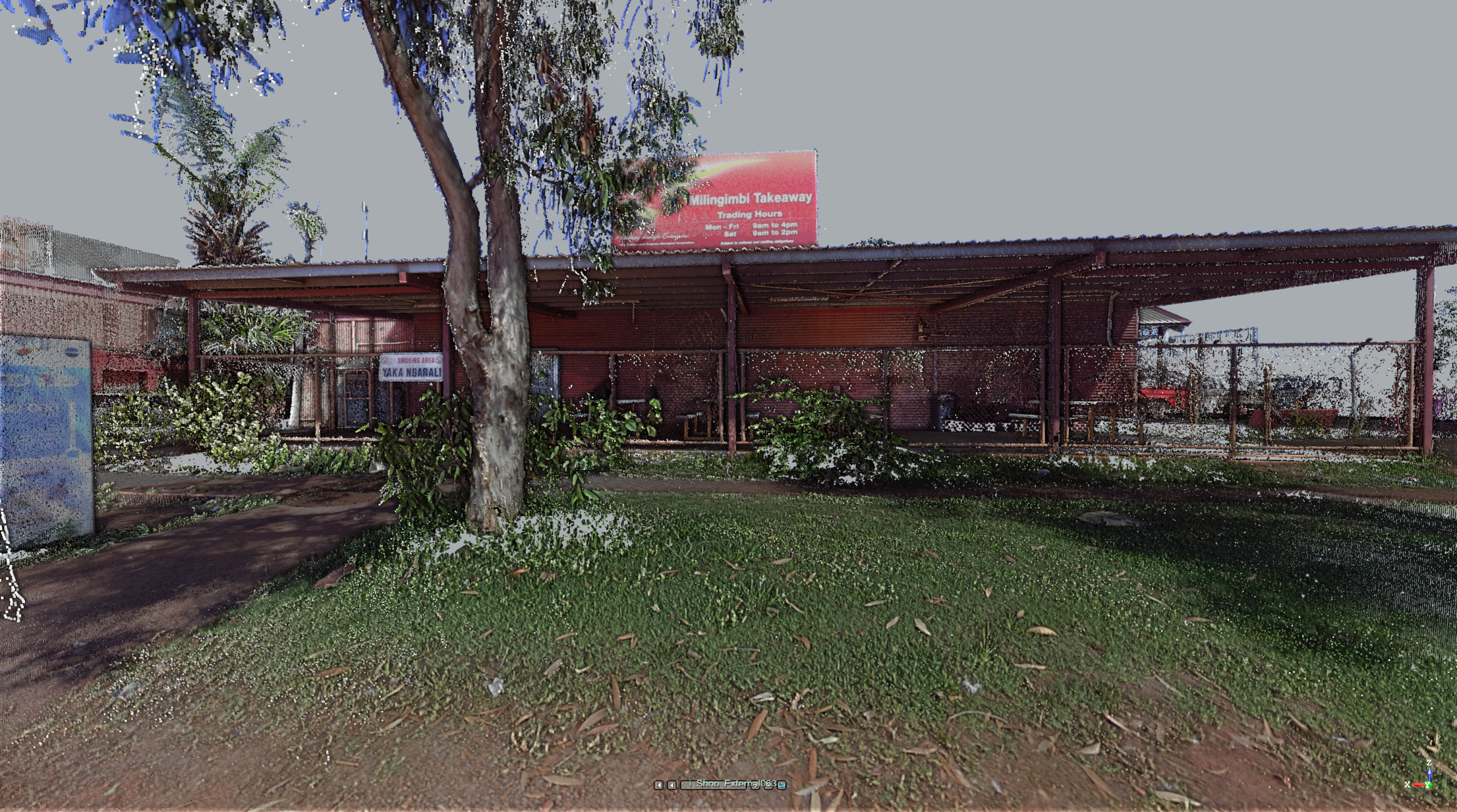

ALPA was proposing improvements to its Milingimbi Community Store to better service the needs of the community, so the Holovision NT Spatial Team performed laser scanning of the full facility.

BENEFITS TO CLIENT

OUR SOLUTIONS