3D Laser Scanning enables you to capture a real-world environment or structure in three dimensions. The resulting 3D information – a point cloud of millions of surveyed points – can create a number of different deliverables. But, what are the benefits of 3D Laser Scanning?

1. Detailed & Accurate – Down to the Millimeter!

3D Laser Scanning works by shooting millions of laser points per second to capture the full internal and external detail of any building, environment or structure. This means whatever we are capturing the data is going to be extremely accurate.

By registering the data from the scans, a 3D point cloud model of the scanned site or object can be created with an accuracy of +/- 1 millimeter. We can then pull measurements from this data from from the comfort of our office. There is no need to re-visit paperwork, decipher messy notes or go back to site for missed measurements. Human error is eliminated.

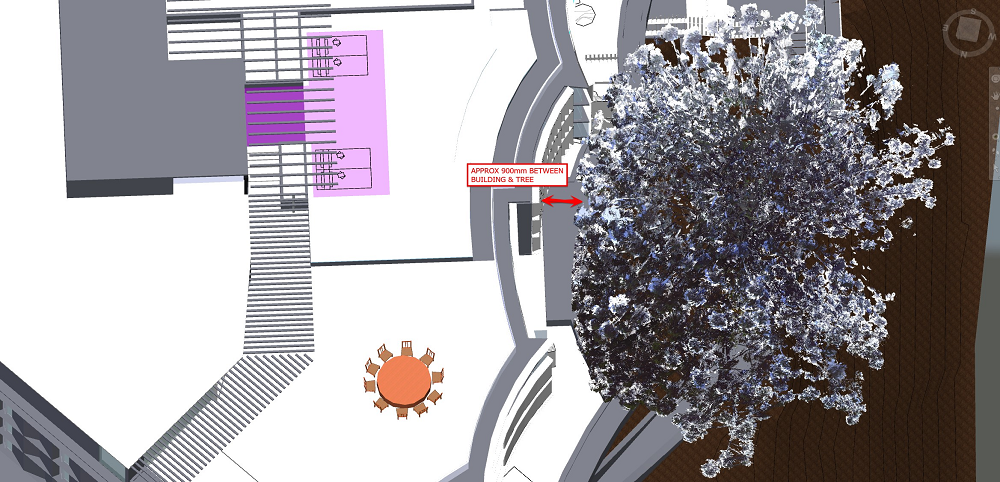

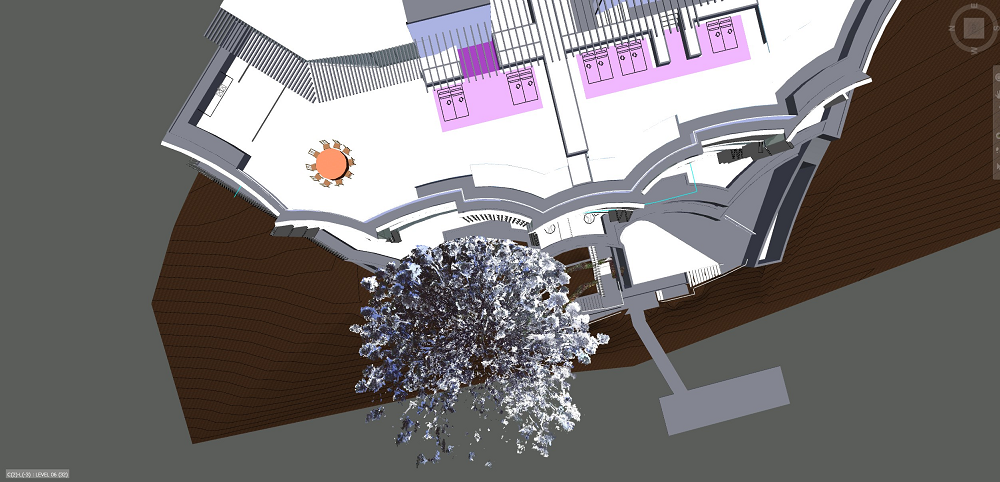

See Case Study: Protected Tree

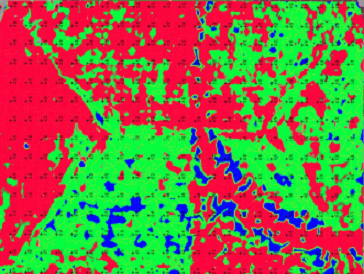

2. Fast & Effective

Traditional surveying with a tape measure is time consuming. It can often take a full day, with multiple visits back to site after, for missed measurements or mistakes. Depending on the size of the site, 3D Laser Scanning can take just half a day. One full scan takes less than 2 minutes!

Because all the data is captured and registered back in the office, you will never go back to site again. You can simply pull up the scan and measure an area of the site or object from your desk. You can even share it easily with project stakeholders.

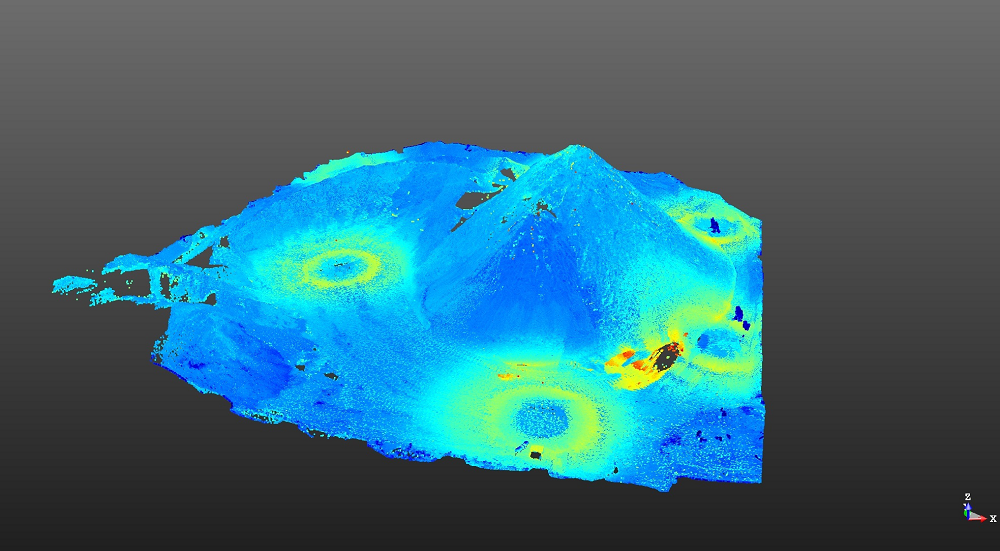

See Case Study: Floor Flatness Reporting

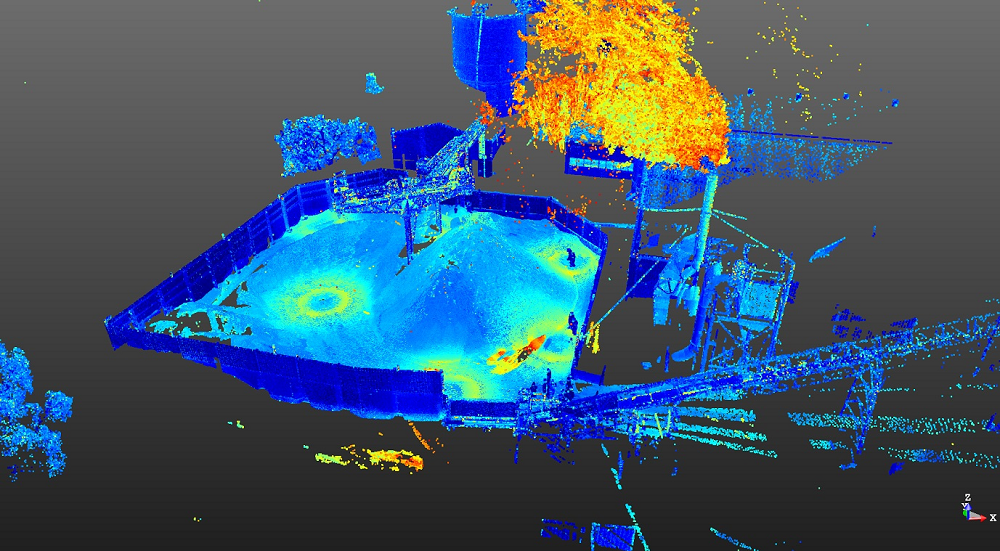

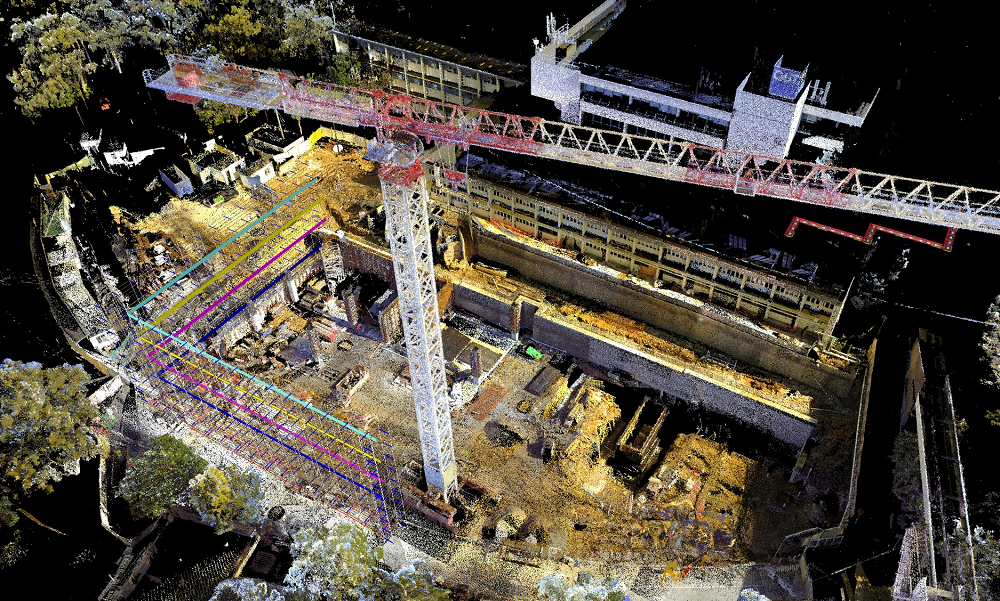

3. Remote Survey Where Direct Access Not Possible

Survey areas, especially construction sites, are not always safe. There may be instances where access to site is restricted or not possible at all. 3D Laser Scanning allows for remote surveying where an individual does not need to directly access or work over the site.

This significantly reduces safety risk and time spent waiting around.

See Case Study: Volumetric Reporting of Sandpiles

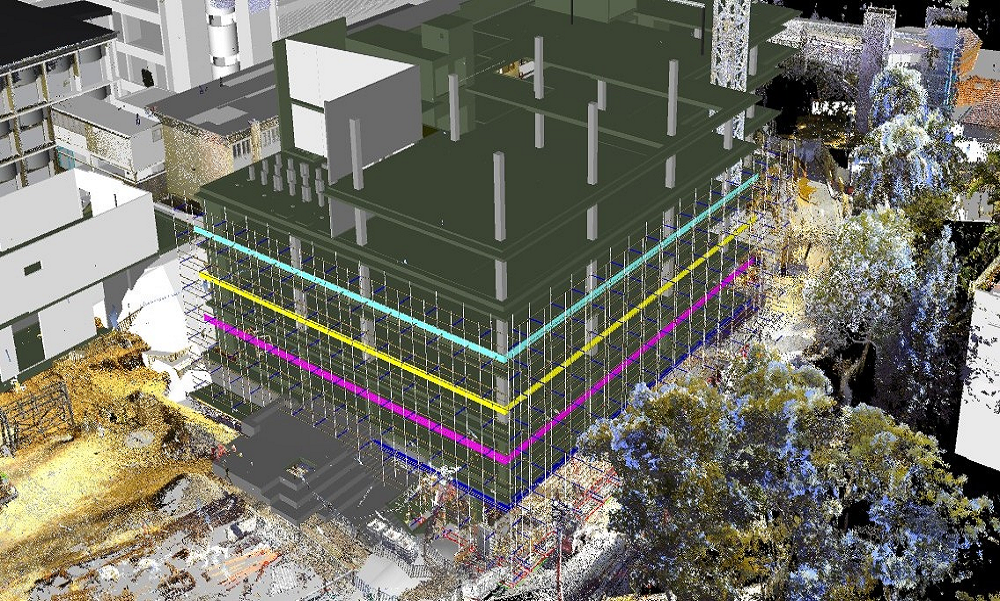

4. Clash Detection

Using our 3D modelling software we are able to overlay a design model onto the 3D laser scan. This ensures fit and highlights any clashes there may be in the environment. By finding this out before construction starts, you will save time and money on reworks.

See Case Study: Scaffold Design & Setout

5. Reduce Risks & Costs

Lastly, thanks to all the above your construction risk and costs will be reduced! Using 3D Laser Scanning human error is eliminated, leaving no room for avoidable mistakes.

Want more information? As each project is unique, please drop us a line and we will get back to you ASAP.